Could you imagine powering your electronic devices with simple motion, such as walking? What if we had wearable medical sensors that never needed to be charged? Recent advances in nanotechnology may make that a reality.

A material that builds up electric charge in response to a physical force is called a piezoelectric material. Certain ceramics have a large piezoelectric response, but they are stiff and brittle and would not work well for a wearable electronic device. Something flexible is better. One type of flexible material is called a polymer, such as what is used in plastics. Some polymers also give a piezoelectric response, most notably Ploy(vinylidene) fluoride, or PVDF for short.

Although PVDF is an attractive candidate for wearable electronics, its piezoelectric response is only about one quarter of the response produced in piezoelectric ceramics. The researchers learned that other scientists combined PVDF with either ceramics or conductive nanomaterials to improve the response and maintain its flexibility. However, if the amount of conductive nanomaterials was too high, the electric current flowed too quickly and the piezoelectric response was lower.

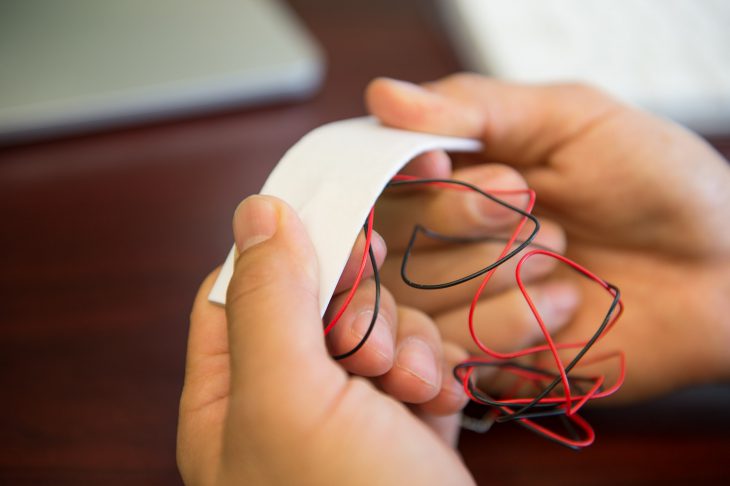

The scientists in this study chose to add barium titanate (a common piezoelectric ceramic) and copper nanowires (a conductive nanomaterial) to PVDF. A copper nanowire is about 1/1000 the width of a human hair. The samples were made by mixing the three materials in a liquid solution for 3 hours to ensure the nanomaterials were evenly dispersed. They then added a drop of this solution to a silicon wafer and allowed the liquid to evaporate overnight, leaving behind a thin film. The film was then heated through a process called annealing to improve its flexibility. The resulting sample was a flexible film.

They made nine samples of this new material, varying the amount of copper nanowires from 0% to 0.08% of the total volume of the material. The barium titanate nanoparticles were 15% of the total volume.

The piezoelectric response occurs because a force such as compression changes the distance between the atoms in the material, separating their positive and negative charges. The positive ends point in the direction of the current – this is called polarization. A good piezoelectric material will become highly polarized in response to electrical stimulation.

The scientists performed two main experiments on the samples in order to investigate the piezoelectric properties. In the first experiment, they applied an alternating electric current across the sample that ramped up to a positive voltage and then down to a negative voltage. They measured the change in the electric charge of the sample as the electric current increased and decreased to determine which sample had the highest polarization.

In the second experiment, the scientists directly measured the energy created by the PVDF film under a mechanical force. They attached each sample to a device that measured the electric current created in the material. They then applied a force to each sample using a pushing instrument that would press and release the film. Their goal was to find the copper nanowire concentration that led to the highest polarization in the first experiment and also created the most energy in the second experiment.

The results of the first experiment showed that the net polarization increased as copper nanowire content increased until 0.04% volume. The addition of copper nanowires initially increased polarization because the conductivity of copper effectively strengthened the electric field.

However, adding too many copper nanowires, over 0.04% volume, decreased the polarization in the sample. One reason this happened is that electricity flowing out of the sample, known as leakage current, increased. The authors also hypothesized that the additional nanowires also likely create small defects in the sample. These defects could prevent the positive and negative ends of the atoms from aligning with the applied electric field.

In the second experiment, they found that the electric current produced in each sample under compression increased with increasing copper nanowire content until 0.04% volume. At higher copper concentrations, the electric current produced under compression decreased.

The scientists computed the power per square centimeter of material, shown as a unit called pW/cm2, that each sample generated based on the results of the above experiment. They showed that by adding 0.04% volume nanowires, the material created 38.78 pW/cm2 compared to only 7.46 pW/cm2 in a sample with no nanowires, an increase of 520%. This means the material can do 520% more work.

The addition of copper nanowires to PVDF dramatically increased the power that the material can produce. However, adding too much conductive nanomaterial lowers the amount of power produced. Therefore studies like this are crucial to identifying the “sweet spot” that will create a device that generates larger amounts of power, bringing us one step closer to the development of wearable electronics.